- 02 de junio de 2021

PRODUCTIVE SYSTEMS

Specific information for Higher University Technicians in Industrial Processes in the Manufacturing area

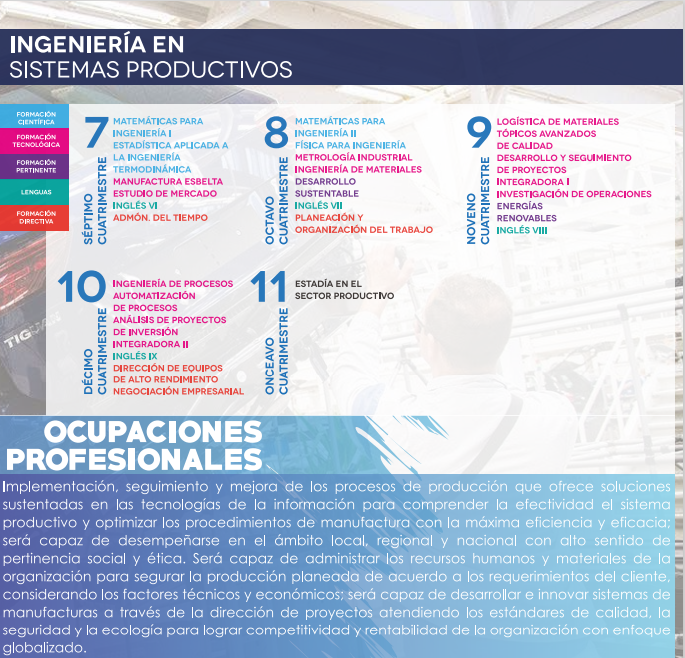

Specific Competencies:

- Manage the necessary resources of the organization to ensure the planned production according to customer requirements.

- Manage human, technical, economic, and material resources of the company. To make the production plant more efficient, through the master production plan, based on the process design.

- Implement the master production plan to meet the requirements of production through the standards of process, product, and plant capacity.

- Control the human factor and the material, economic and technical resources to preserve the integrity of the company’s resources through the pertinent internal norms and regulations, considering the safety and hygiene measures at work.

- Manage the quality management system, with a systemic approach, according to customer requirements, considering technical and economic factors, contributing to sustainable development.

- Manage the quality systems of an organization, to standardize the processes, through the elaboration of a manual of quality that allows fulfilling the requirements of the client, contributing to sustainable development.

- Ensure product quality to meet customer requirements, through the systemic evaluation of the process.

- Develop and innovate manufacturing systems through project management considering customer requirements, quality standards, ergonomics, safety, and ecology to achieve competitiveness and profitability of the organization with a globalized approach.

- Manage projects for the development of new processes, products, and services that meet the needs of the market through a business plan that includes technical market analysis, financial and technological supported by critical path tools for monitoring and control, as well as costs.

- Design products that meet customer expectations under international quality standards, applying technologies that contribute to sustainable development, to improve the company’s competitiveness.

- Develop manufacturing engineering systems based on the value chain of the product or service, to meet the requirements of design, productivity, quality, ergonomics, safety and ecology.

Labor Field

The Productive Systems Engineer will be able to work in:

- The economic sectors: extractive, manufacturing and services, private or public, developing their professional skills, with a sustainable approach, that allow them to apply their skills related to the design and development of products, design, and implementation of processes, management of operational and administrative activities of a plant or company, including the implementation, development and control of projects.

The Production Systems Engineer will be able to work as:

- Engineer, Head of Area, Superintendent, Manager, Director, in areas of:

Production, Quality, Product Engineering, Manufacturing Engineering, Logistics, Technological Innovation, Projects, Technical Support, among others. In addition to Consultant and Entrepreneur.

Curriculum Map